Sensor Monitor Photo Gallery

Here are some examples and details of Sensor Monitor implementation

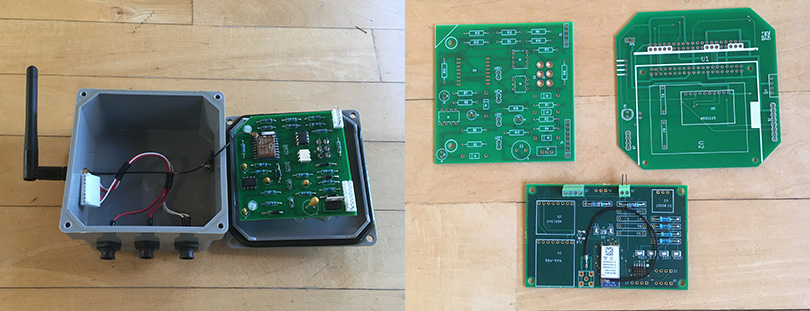

This Sensor Monitor is packaged in a standard 4x4 electrical box. It features an external WiFi antenna, mil-spec connectors, two analog input channels, and one digital input. A custom printed circuit board contains the microprocessor core and the supporting digital and analog circuitry. The firmware provides for setup and configuration and periodically uploads data to a cloud platform. Also shown are other printed circuit boards that we have designed in house. We have processes in place to rapidly design and manufacture printed circuit baord based solutions for quantities as small as ten units.

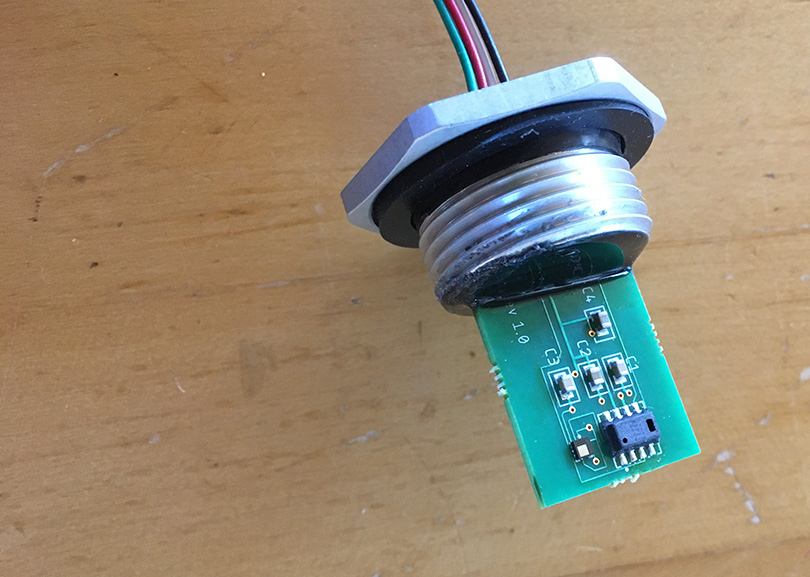

This custom sensor monitors temperature, humidity, and barmetric pressure inside an environmentally sealed container. We have combined off the shelf smd sensors, a custom printed circuit board, and a hermetic seal into a specific form factor which threads into an existing port in the container.

This Sensor Monitor combines an ARM based CPU core running Linux with WiFi and Bluetooth communications to create a mesh networked device which will collect and forward sensor data. These devices are undergoing post manufacturing burn in testing prior to deployment.

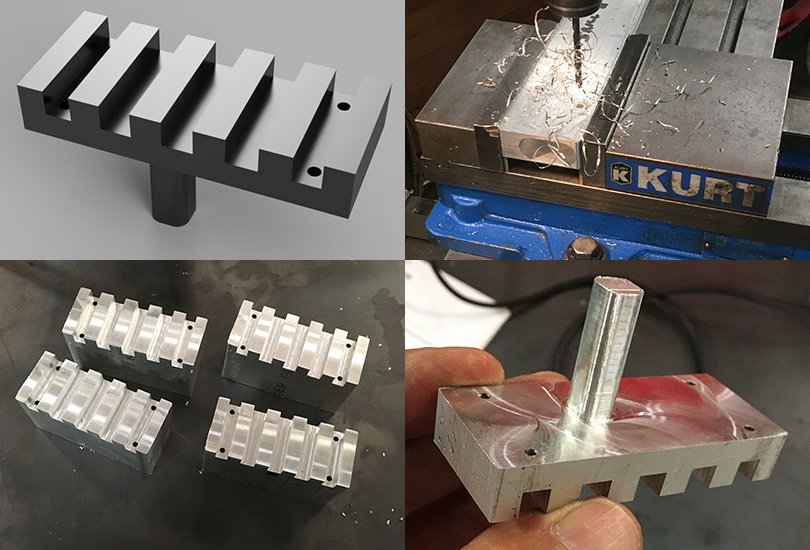

This customized heatsink was designed using CAD and manufactured using CAM processes on a CNC milling machine.The MONITORING COMPANY has the CAD design and CNC manufacturing facilities to produce customized parts such as heatsinks, mounting brackets, and enclosures. We also customize off the shelf products to acheive optimum costs.

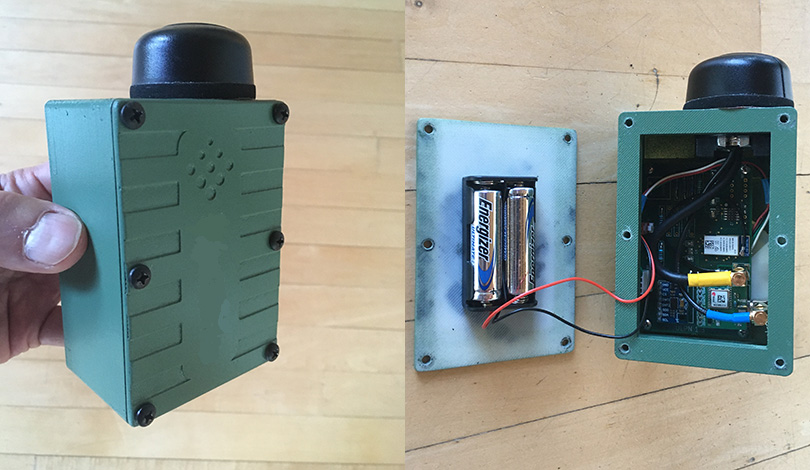

This Sensor Monitor is battery powered, equipped with GPS and various outher sensors, and communicates using Bluetooth. It is packaged in a custom designed enclosure the prototypes of which were 3D printed. Data is sent periodically, or when a qualifying event is detected.

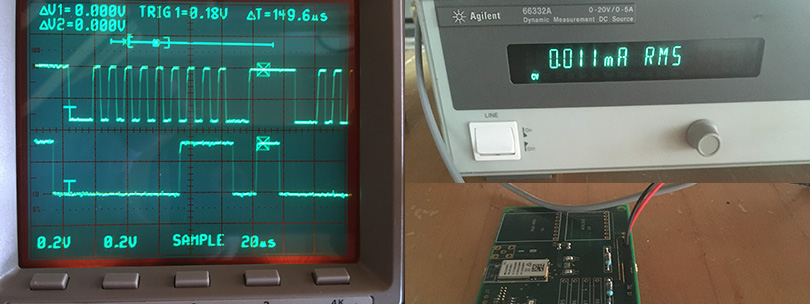

Engineering and testing are part of what we do. The first picture shows a timing analysis of a digitally connected sensor that was done to help resolve a timing concern. After the signals were observed the firmware was modified to optimize the sensor readings. The second picture shows power consumption testing of a Sensor Monitor. This particular device collects and reports data less frequently and is powered by batteries. As part of the development process the device is tested and firmware created to manage the power consumption of the device such that battery life is measured in years.